To meet the stringent requirements of the defence industry, we operate segregated, high-security manufacturing cells within our Indian facilities.

We adhere to the strict requirements of the International Traffic in Arms Regulations (ITAR) for controlled technical data and hardware, establishing VAC as a reliable and secure partner for foreign defence clients.

The massive 217,800 sq ft facility is being developed with a Level-4 Secured Zone dedicated to final integration and testing of complex defense sub-assemblies near a major port city.

A specialized 15,000 sq ft unit within the NCR campus dedicated to the 5-axis machining of exotic alloys under strict access control, ensuring product integrity and security.

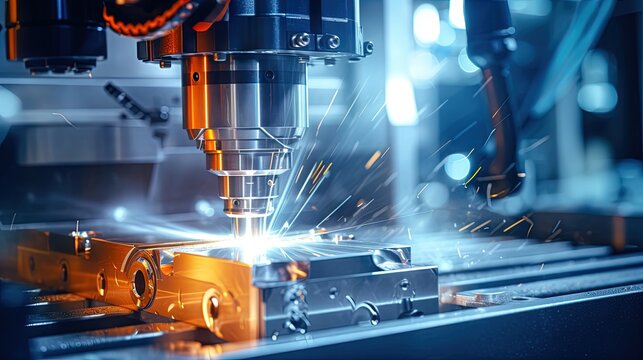

Our facilities utilize highly calibrated, multi-axis machinery and specialized processes designed for zero-defect component manufacturing.

Employing high-speed VMCs for complex geometric features and high surface finish required for gimbal mounts and optical components.

Achieving sub-micron tolerances on single setups.

Utilizing 4KW AMADA Laser with certified processes for aerospace-grade aluminum and specialized composites, ensuring material integrity.

Process certifications guarantee material stability.

Environmental-controlled booths for orbital TIG and vacuum furnace brazing of titanium and stainless steel for flight-critical structures.

Ensuring robust, defect-free joints compliant with military standards.

We specialize in machining and fabricating high-performance materials essential for reducing weight and increasing the survivability of defense hardware.

We have a 30-year track record producing a wide range of backhoe loader parts for leading Original Equipment Manufacturers (OEMs), built on consistency and trusted partnership.