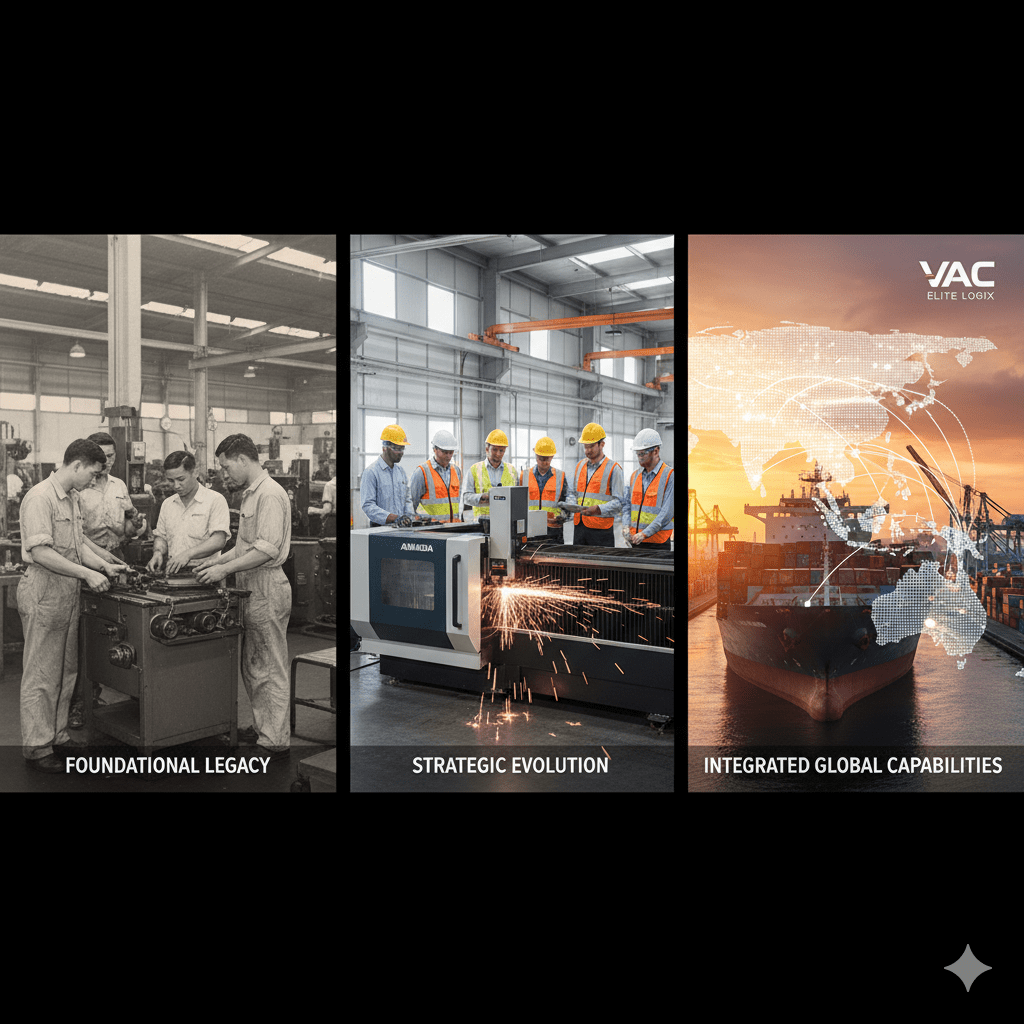

From foundational manufacturing excellence to an integrated global partner, our story is built on continuous evolution and unwavering commitment to quality.

Legacy: A vintage black-and-white photo of the original 1967 factory or a worker.

Evolution: A professional photo of the modern leadership/management team or the full Faridabad facility.

Capabilities:A photo of the CNH or JCB part assembly line or the Laser Cutting Machine in action.

To be the leading trusted partner for high-quality allied components in Southeast Asia, empowering industries through innovation, reliability, and sustainable manufacturing practices that drive progress and strengthen growth.

To consistently exceed global OEM quality standards, maintain operational excellence through Kaizen, and leverage our integrated supply chain to deliver high-value components with unmatched reliability and cost-efficiency.

Our portfolio highlights the integration of precision manufacturing,advanced technology,and strategic global logistics across diverse industrial and defence sectors.

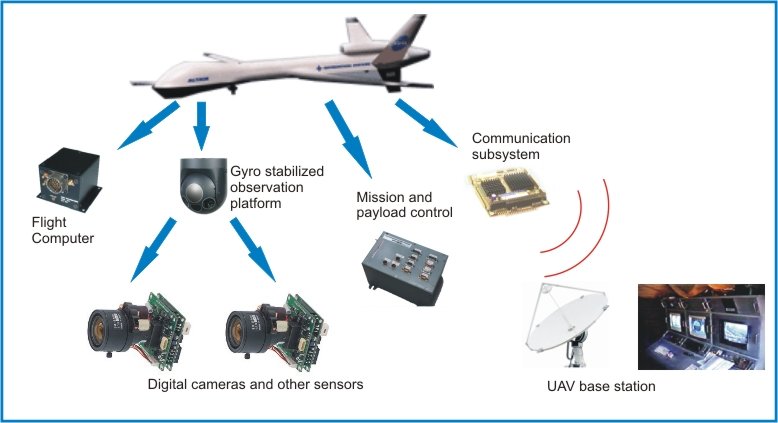

The Challenge: Develop ultra-lightweight, high-strength internal chassis and structural components for a next-generation defence Unmanned Aerial Vehicle (UAV) requiring strict material control. The VAC Solution: Our R&D team deployed Additive Manufacturing (3D Printing) and advanced CNC machining of specialized alloys to produce mission-critical parts, reducing component weight by 15% while exceeding required strength thresholds.

The Challenge: To manufacture and supply over 500 units monthly of complex, high-strength cabins and heavy-duty buckets for a major construction equipment OEM in India (e.g., JCB/CNH). The VAC Solution: We utilized our Hi-Definition CNC Plasma and fabrication bays to achieve precise welding tolerances and consistent quality, ensuring zero downtime on the client’s assembly line.

The Challenge: Streamline the export supply chain of large, finished equipment parts from the Faridabad plant to European assembly points, requiring precise scheduling. The VAC Solution: Leveraging Elite Logix, we managed the entire process, integrating Inland Rail Transportation to the port, Sea Freight booking, and end-to-end Customs Clearance, reducing transit time by 8% and achieving a 99.8% on-time delivery rate.

The Challenge: Rapidly establish a new high-volume production line for thousands of diverse sheet metal assemblies for a major international mining equipment manufacturer (e.g., TEREX/METSO). The VAC Solution: We installed new AMADA Laser Cutting capacity and leveraged our experienced team to quickly ramp up production. This dedication to delivery and quality led to the TEREX Best Supplier Award 2023.